Dear Ham Radio Operators and AMSAT-TR Friends,

The final touches are nearly being completed for “TURKSAT–3USAT” LEO Communication Satellite, to be placed in its 680 Km orbit in May,2013. As defined by the program; V/U TRANSPONDER’s designed and produced by AMSAT-TR; have been pre tested before the integration phase, in Istanbul Technical University (ITU) – Space Systems Design and Test Laboratuary (USTTL) and we are invited to participate this test. A.Tahir DENGIZ, TA2T, President and Baris DINC, TA7W Vice President were at the Laboratuary in February, 09 th,2013.

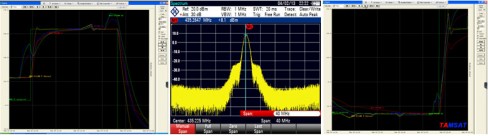

Before the start, the detailed information were given about, the results of the preliminary tests, the TVAC Test Chamber, the specifications of the sensors, the order of the test steps, the logic for them and the limit values to be fallowed. You can see the preliminary test result samples in Fig.1.

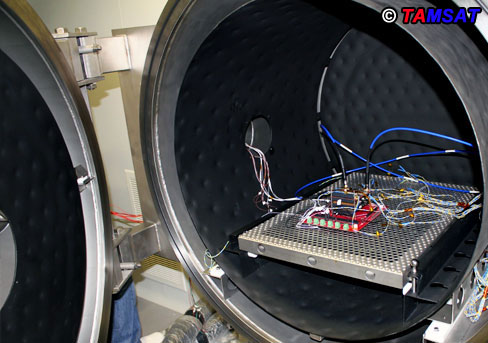

Having these informations, Baris, TA7W prepared the TAMSAT U/V TRANSPONDER connections to be put in TVAC Chamber, as you see in Fig.2.

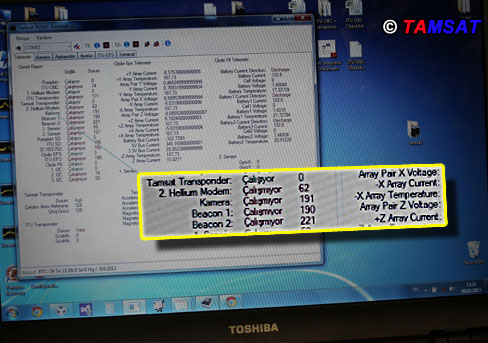

The special software written for TVAC Chamber as shown in Fig.3; which will record all the logs during the test, has been setup by the test team.

TAMSAT V/U TRANSPONDER which has been prepared fort he test with the sensors has been placed in the TVAC Chamber as seen in Fig.4. and connected to the computer.

The “CLEAN ROOM” for this test (Class 1000 type) is controlled carefully. It is free from dust and any particles and the test team maintain this conditions. Every team member enters this room using shoe covers/special slippers, head covers and Lab Shirts; passing through two seperate isolated rooms to preserve the constant temperature and humidity. As seen in Fig.5. I followed the test behind the Windows.

The tests will start when the pressure in the TVAC Chamber drops to 10-3 Pascal, and it took 5 hours. This is a long time for Baris, TA7W as you see in Fig.6.

At last, the testing conditions were ready; after starting the heating cooling cycles Baris, TA7W started the communications tests as it is seen in Fig.7.. He has a smiley face after seing the results.

Before starting the evaluation of the results logged by the software, the test team is gathered in Fig.8.

After the evaluation of the test logs; they will be presented in another note. We thank all of the participants for this Project and the tests. We are sure that, having these practices and knowledge, the following studies will be completed quicker.

A.Tahir DENGİZ, TA2T

AMSAT-TR

Turkish Amateur Satellite Technologies Organization